3D printing technology (Three Dimensional Printing, 3DP), also known as "additive manufacturing" or "additive manufacturing", is a disruptive manufacturing technology. It is different from traditional material processing methods. It is based on 3D CAD model data and builds 3D entities by adding materials layer by layer. This technology can directly produce 3D physical entities that are completely consistent with mathematical models, covering the entire process from "rapid prototyping" to "rapid manufacturing". It involves a wide range of technical fields, including CAD modeling, precision machinery, laser technology, etc., showing the charm of multidisciplinary integration.

In recent years, 3D printing technology has received widespread attention around the world. The British magazine "The Economist" even praised it as a landmark technology of the third global industrial revolution, heralding a profound change in the manufacturing industry. The US "Time" magazine also listed 3D printing as "the ten fastest growing industries in the United States", highlighting its popularity around the world. At the same time, domestic media, academia and the financial community have also plunged into the craze for 3D printing technology, and government departments at all levels have also begun to formulate development plans for 3D printing technology.

3D printing technology (Three Dimensional Printing, 3DP), also known as "additive manufacturing" or "additive manufacturing", is a disruptive manufacturing technology. It is different from traditional material processing methods. It is based on 3D CAD model data and builds 3D entities by adding materials layer by layer. This technology can directly produce 3D physical entities that are completely consistent with mathematical models, covering the entire process from "rapid prototyping" to "rapid manufacturing". It involves a wide range of technical fields, including CAD modeling, precision machinery, laser technology, etc., showing the charm of multidisciplinary integration.

In recent years, 3D printing technology has received widespread attention around the world. The British magazine "The Economist" even praised it as a landmark technology of the third global industrial revolution, heralding a profound change in the manufacturing industry. The US "Time" magazine also listed 3D printing as "the ten fastest growing industries in the United States", highlighting its popularity around the world. At the same time, domestic media, academia and the financial community have also plunged into the craze for 3D printing technology, and government departments at all levels have also begun to formulate development plans for 3D printing technology.

【Global Attention and Influence】

3D printing technology has received widespread attention from the world and is believed to bring about important changes in the manufacturing industry. It has been listed as one of the fastest growing industrial technologies by many authoritative media.

Advantages and classification of 3D printing technology

【Unique advantages of technology】

Compared with traditional printing methods, 3D printing technology exhibits many unique characteristics and significant advantages:

- Digital manufacturing:

Through software such as CAD, the product structure is digitized, and then the machine equipment is driven for processing and manufacturing. This manufacturing method is not only flexible, but the digital files can also be transmitted remotely through the network to achieve a decentralized production model.

- Dimension reduction manufacturing (or layered manufacturing):

3D printing technology decomposes three-dimensional objects into two-dimensional layered structures layer by layer, and then accumulates layer by layer to eventually form complex three-dimensional objects. This manufacturing method enables 3D printing to produce any complex structure, and the process is more flexible.

- Stacking manufacturing:

3D printing adopts a "bottom-up" stacking method, which has significant advantages for realizing devices with non-uniform materials and functional gradients.

- Direct manufacturing:

Through 3D printing, any high-performance and difficult-to-form parts can be directly manufactured at one time without going through a complex assembly and splicing process.

- Rapid manufacturing:

The manufacturing process of 3D printing is short, fully automatic, and can be manufactured on site, so it has higher manufacturing speed and efficiency.

[Technical classification and standards]

In addition, 3D printing technology also has a variety of classification methods. According to different materials, 3D printing can be divided into types such as block materials, liquid materials and powder materials. At the same time, the 3D Printing Technology Committee (F42 Committee) of the American Society for Testing and Materials (ASTM) has also formulated relevant standards, and has made detailed classifications of seven types of 3D printing processes and materials used. At present, the 3D printers that have been commercialized on the market mainly use seven types of processes, among which SLA (stereolithography), SLS (selective laser sintering), FDM (fused deposition modeling) and 3D printing processes have attracted much attention.

Main 3D printing processes and procedures

[Stereolithography (SLA)]

The first is SLA, which uses ultraviolet light to scan the surface of liquid photosensitive resin. After each scan, a thin solidified layer is generated, which is stacked layer by layer from the bottom to form a three-dimensional object. The advantage of this technology is that the raw material utilization rate is extremely high, the dimensional accuracy can reach ±0.1mm, and the surface quality is also quite good, which can produce models with extremely complex structures. However, its disadvantages are also obvious, mainly including high prices, limitations on material types, and possible disintegration of finished products under long-term light exposure.

Understand the specific production process of SLA. This technology mainly relies on ultraviolet light to scan the liquid photosensitive resin finely, and builds three-dimensional objects by curing and stacking layer by layer.

The production process includes the following key steps:

First, place the liquid photosensitive resin on the workbench;

Second, use ultraviolet light to scan the resin surface finely to generate a solidified layer;

Then, the workbench is lowered a certain distance, and a new round of scanning and solidification is performed;

This process is repeated until the entire three-dimensional object is completed.

This process requires not only precise equipment control, but also professional operating skills to ensure the quality and accuracy of the final product.

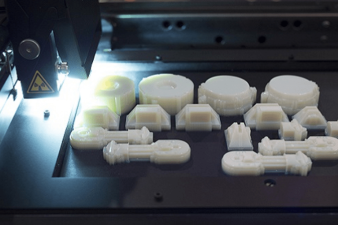

[Selective Laser Sintering (SLS)]

Next is selective laser sintering printing (SLS), referred to as SLS, which is a 3D printing technology that uses high-power lasers to heat and sinter powder into parts. Its advantage is that it can process metal materials and a variety of thermoplastics, such as nylon, polycarbonate, polyacrylate, etc., and no support is required during the printing process. The printed parts have excellent mechanical properties and high strength. However, this technology also has some shortcomings, such as the material powder is relatively loose and the molding accuracy after sintering needs to be improved. At the same time, the cost of high-power lasers is relatively high. SLS technology is commonly used for 3D printing of polymers and can be extended to the manufacture of metal or ceramic parts. However, it should be noted that the density of its products is low and usually requires subsequent densification treatment to meet the use requirements.

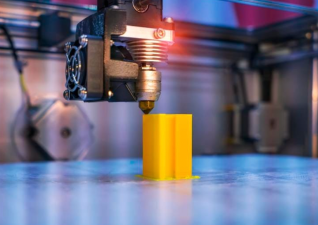

[Fused Deposition Printing (FDM)]

Fused deposition printing, also known as Fused Deposition Modeling, is a 3D printing technology that melts plastic fiber materials through a hot melt nozzle and extrude them out of the nozzle, and then solidifies and forms them at a specified position. Its process is similar to "squeezing toothpaste" and has the advantages of low cost, small equipment size, and relatively simple operation. However, this technology also has some shortcomings, such as obvious stripes on the surface of the molded parts, weak interlayer bonding strength, and slow printing speed. FDM technology is one of the most basic and widely used processes in the field of 3D printing, and is often used in desktop 3D printing equipment.

[3D printing (3DP)]

The last one to be introduced is 3D printing technology, also known as three-dimensional solid printing, which works similarly to an inkjet printer. This process is different from selective laser sintering, mainly reflected in the application of nozzle bonding and binder injection heads. The significant advantages of 3D printing are its high-speed printing and cost-effectiveness. However, the mechanical strength of its products is relatively low. Currently, 3DP technology has been widely used in full-color 3D printing and sand casting.